The key aspect for the SCS RAPID Component SDD is the placement of the SMA rods outside the column and core. In this location they can be readily inspected and replaced without taking the bridge out of service. The core design essentially matches the design of the column below, so there is no change in elastic capacity for axial force and moment below the SDD. Based on the UNR testing, the most likely damage to a SDD is to the SMA rods. If the core ECC is cracked that can also be repaired from the sides without removing the SDD from the bridge. The SMA rods are used to their best effect for tension loads and are isolated from compression loads. This allows SMA cables to be used in lieu of SMA rods in some applications.

The Fairing

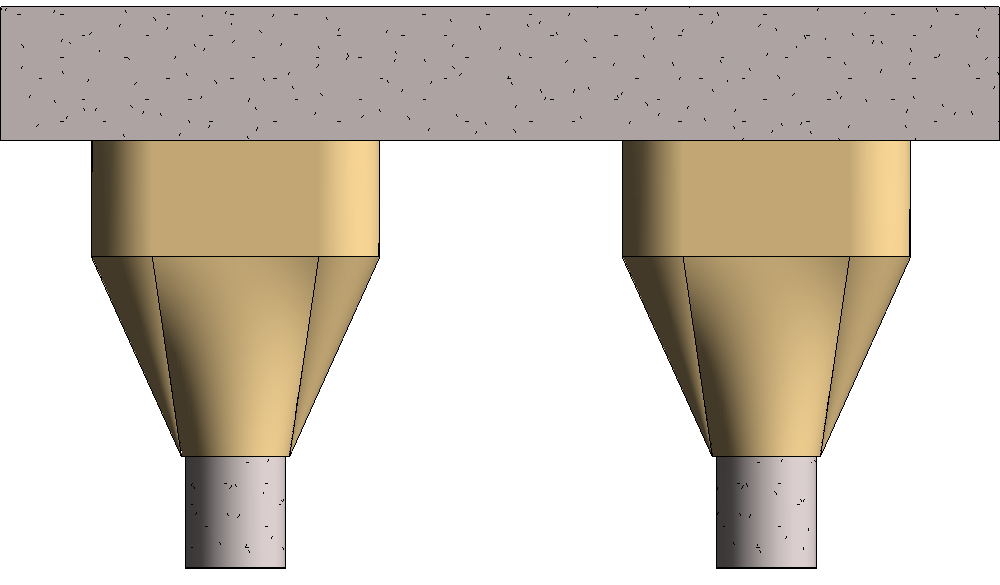

Obviously the downside to moving the rods outside the column is that the rods and portions of the plates they connect would be exposed to the environment. One of the guiding principles in concrete structures of all types is to bury steel within the concrete for environmental protection. The SMA Nitinol material is highly corrosion resistant –one of the major commercial applications for Nitinol is orthodontia and medical implants. However, the steel plates would still be susceptible to corrosion as would nuts and other hardware. However, using concrete cover is not the only way to protect the SDD’s metal components. The SCS RAPID column system uses a fairing cover made of fiberglass or GFRC to protect the SDD connection. This fairing seals to the column and the girder above or the foundation below if the SDD is at the bottom of the column.

This solution offers several advantages:

- The architectural appearance can be separate from the concrete structural members. Current practice is to use custom formwork to pour in place columns with flares or other features (flared column tops are very popular). The custom formwork is very expensive and the odd shapes of the flare columns can lead to seismic performance issues . As the fairing does not support bridge loads it can be of any configuration that will protect the connection from the environment.

- The fairing allows inspection of the rods and core through built-in ports. The fairing can be removed to provide complete access as needed for repair.

- The fairing has space for instrumentation for bridge monitoring. Conduits connecting the SDD space to the girder and column can be placed within the girder and/or column respectively. This allows internal routing of instrumentation wiring.

- The fairing can host signage or lighting with wiring accessible inside the fairing.

Structural Component Systems, Inc.

Think Outside the Column

Accelerated Bridge Construction Components

Copyright (C) 2015 SCS. All Rights Reserved. Patent Pending